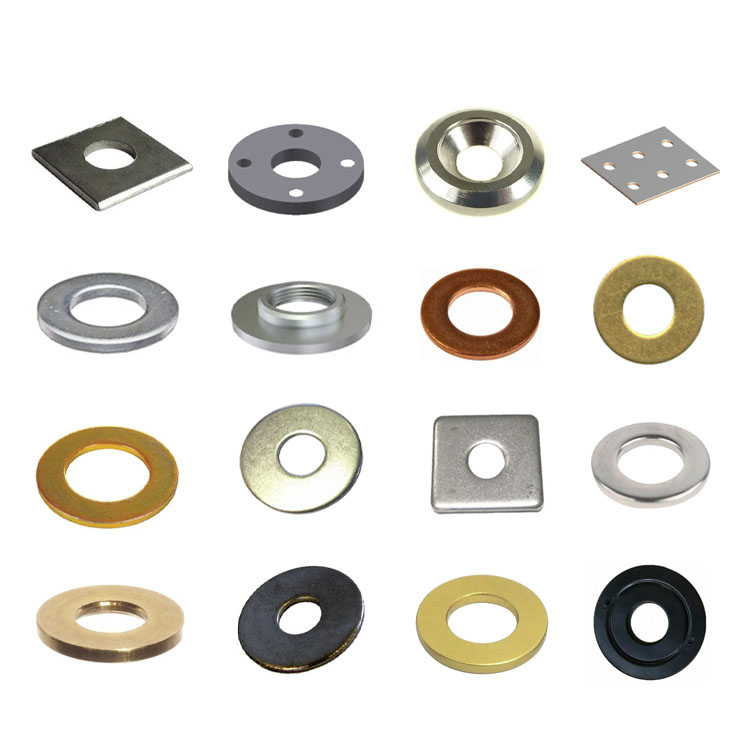

PRODUCT DETAIL

JCEN, a leader in advanced metal fabrication, offers Custom Metal Shims & Washers designed to meet the most demanding industrial requirements. With decades of expertise, JCEN integrates cutting-edge technology, material diversity, and stringent quality protocols to deliver solutions for automotive, aerospace, energy, and machinery sectors.

Advanced Manufacturing Processes

JCEN employs state-of-the-art techniques to ensure precision and durability:

- Laser Cutting & CNC Machining: For ultra-precise dimensions and complex geometries, ensuring perfect fitment in high-tolerance assemblies.

- Stamping & Forming: High-speed stamping presses produce large batches efficiently while maintaining consistency in thickness and surface finish.

- Surface Treatments: Options like galvanization, anodizing, and passivation enhance corrosion resistance and adapt washers to harsh environments.

Material Versatility

JCEN’s metal washers are crafted from a wide range of materials to suit diverse applications:

- Stainless Steel: Ideal for corrosion resistance in marine or chemical industries.

- Copper & Brass: Used in electrical systems for conductivity and thermal management.

- Aluminum: Lightweight yet durable, perfect for aerospace and automotive weight reduction.

- Special Alloys: Titanium or Inconel® for extreme temperatures and pressures.

JCEN’s engineers guide clients in selecting optimal materials, balancing cost and performance.

JCEN prioritizes secure and sustainable packaging:

- Anti-Corrosion Packaging: Vacuum-sealed bags with desiccants for moisture-sensitive environments.

- Custom Labeling: Barcodes, QR codes, or client-specific identifiers for traceability.

- Bulk & Retail Options: From industrial-sized pallets to small, retail-ready boxes.

Quality Control

PREV: Welding & Riveting Parts